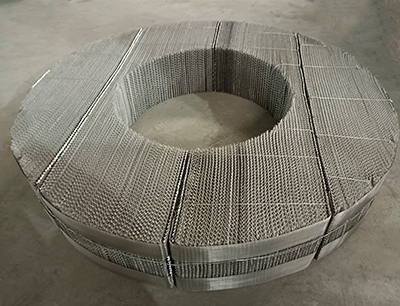

Stainless steel wire mesh packing

Stainless steel wire mesh packing

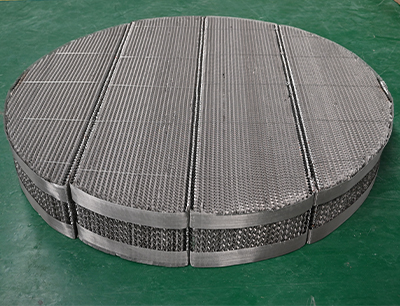

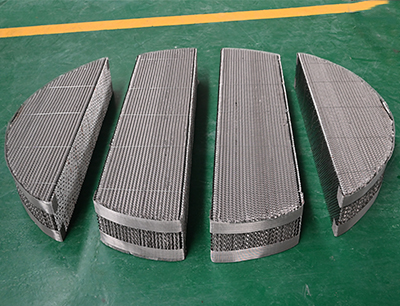

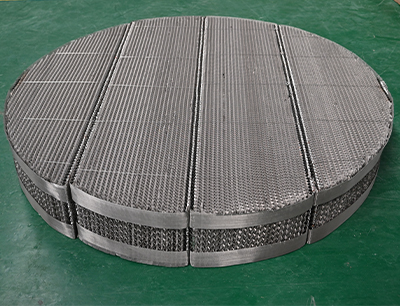

Product name: Wire mesh corrugated packing

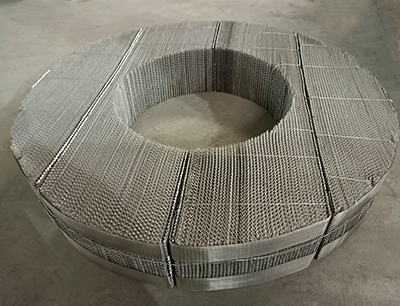

Product material: stainless steel wire copper wire low carbon steel wire nickel wire aluminum wire pure titanium other special materials can be customized according to user requirements.

Specifications/types/parameters: e.g. W700(CY) W500(BX) etc.

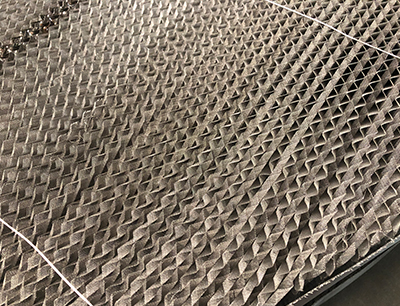

Ripple tilt direction: X (representing the ripple and tower axis tilt 30°) Y (representing the ripple and tower axis tilt 45°) X packing pressure drop is small; Y-type packing has better mass transfer performance production process: it is composed of a number of corrugated wire mesh sheets in parallel, corrugated sheet inclination of 30° or 45°, and adjacent two corrugated sheets in the opposite direction composed of disc-shaped packing. When filling in the tower, the upper and lower plates are stacked 90°.

Product features:

1. Large specific surface area, large porosity, light weight;

2. Small inclination Angle, regular, reduced pressure;

3. Good radial diffusion, adequate gas-liquid contact.

Application: fine chemical, fragrance, petrochemical, chemical fertilizer industry, isomer separation, precision distillation and vacuum distillation device, difficult separation system. The distillation and separation of heat-sensitive systems and high-purity products provide an effective means. It is suitable for vacuum distillation tower to deal with materials that are allergic, easy to decompose, easy to compact and easy to bind carbon.

Product introduction: Wire mesh corrugated packing is the main form of mesh corrugated packing, it is made of wire mesh. The pressure of corrugated metal wire mesh packing is reduced and the separation efficiency is very high. Although its cost is high, it is still widely used because of its excellent performance. Products are BX, CY type, often used for difficult to separate and heat sensitive substances vacuum distillation, atmospheric distillation and absorption process.

X-250: Precision distillation with high production intensity and low number of theoretical plates; X-500: Vacuum distillation of heat-sensitive, difficult-to-separate special systems, especially vacuum distillation under pressure of less than 7KPa.

Y-700: Separation of isotopic mixtures and isomers